The abandoned 65-acre Barber-Colman factory complex is a sprawling 795,000 square foot facility that is currently under demolition by the city of Rockford, Illinois. When I first discovered the site I had no idea that it had such an engaging history. Many of the things we consider modern conveniences were developed by the man who made this factory possible.

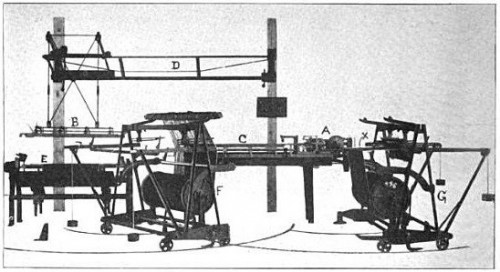

Photo (source): Colman’s warp drawing machine.

At the young age of 17 Howard D. Colman invented a warp drawing machine, which is used to automate the weaving of cotton into patterns. A local lumberman, W.A. Barber, invested $100 so Colman could transform his wooden prototype into iron and steel. With that initial investment the Barber-Colman company was founded. In 1894 the prodigious inventor was granted his first patent for a instrument that measured the flow of milk. This early success, along with the 149 patents eventually granted to Colman over the years, were key in building Barber-Colman. Colman, however, was quite a humble man and often attributed his inventions to his financial backer Barber. He is described in Jon Lundin’s book The Master Inventor as a man who always took the stairs. Photographs of Colman were so rare that employees would pass him by completely oblivious as to who he was.

Photo: The design was submitted by Howard D. Colman himself in 1939.

Photo (source): An arial view of the factory complex taken in 1962.

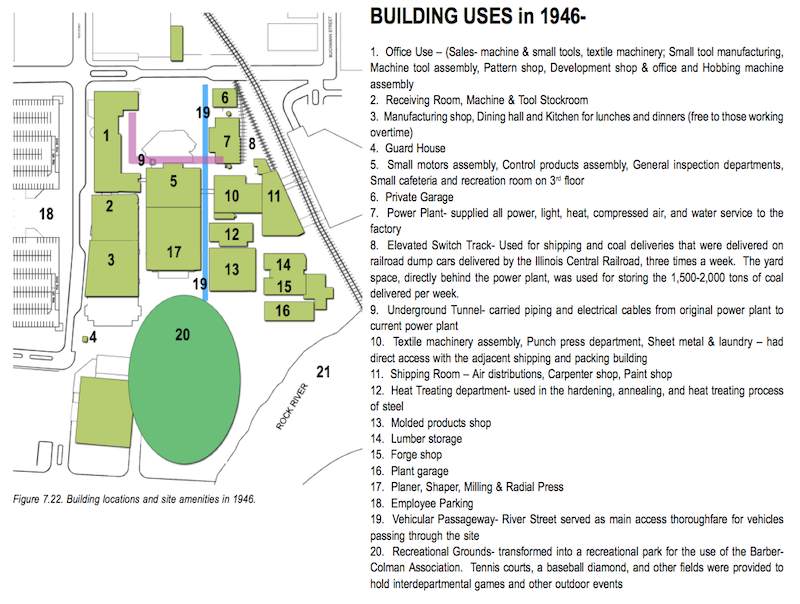

Photo: Barber-Colman site inventory from Christopher Shawn Tofte: Urban Entertainment Destinations A Developmental Approach for Urban Revitalization.

The Barber-Colman factory constructed its first building on the banks of the Rock River and was operational by 1902. By 1916 the company owned the two city blocks and built even more structures to keep pace with market demand. Colman wisely diversified the companies offerings. Products included handheld tools, garage door openers, oscillating fans, office machines, hardness check pumps, plastics manufacturing, air conditioning, avionics, textile hand knotters, milling cutters, gear hobbing machines and of course the warp drawing machine. Investors were not to keen on Colman’s consumer electronics endeavors, but the diversification kept the company solvent all throughout the Great Depression. As with any major industrial business during World War II the company contracted with the US government to make avionics.

Photo (source): A Barber-Colman engineer with a computer that used vacuum tubes for data storage.

Taking innovative risks in a variety of markets paid off for the Barber-Colman company. Allied engineers turned their wartime computing innovations to the private sector after World War II. Computer pioneer George Stibitz built a prototype gear hob control computer in 1950 which was used briefly at Barber-Colman. This computer was one of the earliest to use binary bits to store and process data. (Note: The computer you are using right now is built on that very innovation.) Although they were one of the earliest examples of American businesses using electronic computers, the company decided not to invest in the unproven technology.

Photo: Data punchcards bearing the Barber-Colman logo.

In 1980 the Barber-Colman company decided to relocate their headquarters just north of Rockford, Illinois. The Reed-Chatwood textile company purchased the building in 1984 and held operations there for a few years. Reed-Chatwood did not find the same level of success that Barber-Colman enjoyed at the location and ceased operations in 1996. The property was then put up for auction. The new owners created a business incubator and leased the space out to smaller industrial and office tenants. The venture was eventually shut down in 1999 after the owners failed to pay for utilities. In 2002 the city of Rockford purchased the abandoned property for $775,000 for redevelopment. The city has shown the property to several potential investors, but so far nothing of substance has materialized. In 2009 a fire broke out on the third floor in some of the office spaces. The fire department was able to contain most of the damage to the third floor.

Photo: A lone chair sits alone on one of the massive production floors.

Video: Volunteers rescuing files for preservation from one of the upper floors of the long abandoned factory.

An impressive array of Barber-Colman files were discovered on the 6th floor of one of the buildings after Rockford purchased the property. In 2008 thirty volunteers organized to move 1000 drawings and 500 binders containing Barber-Colman history. The Midway Village Museum is currently cataloguing the find as part of Rockford’s history. Although the Barber-Colman factory is a vital piece of industrial history, it now looms silently next to the Rock River.

Photo: Warning sign on the freight elevator.

This urbex trip turned out to be one of the most intellectually satisfying I have ever been on. I discovered the site late on a Saturday evening and called friends immediately. I just had a gut feeling about it. We arrived at the location early Sunday morning and were instantly awestruck. The volume of subject matter to photograph were overwhelming as we meandered through the buildings. Along the way we came across old machinery, vintage computer technology, some Barber-Colman products, blueprints, personal photos, and other office materials. We even met another photographer who was taking senior photos and a homeless person named Rob. After six hours on-site the sun began to set and we left thoroughly exhausted. There were maybe two or three structures left that we just did not have time to explore.

Photo: Uncut steel slugs for wrenches.

When it comes to urbex I am very conservative. I do my research, contact people who have been to a location, ask pertinent questions, and sometimes scout a location prior to going into it. That was not the case this time around and it heightened the anticipation. It was a kind euphoric rush that I have not felt since my first urbex experience. It was not until I got home that I discovered just how influential this urbex location was. I am grateful that I had a chance to explore it before the factory completely disappears in the coming months.

Colman was a humble genius inventor on par with Edison or Ford, but without the fanfare or celebrity. He genuinely cared for his employees and saw to their welfare by organizing recreational outings, a company band, and sports teams. He also took the steps necessary to insure they kept their jobs during economic depressions. If only the same could be said for today’s business leaders.

Resources:

Flickr – My “Abandoned Barber Colman” Photoset.

Flickr – Photos tagged “Barber+Colman.”

Barber-Colman – Official corporate website listing their current product lines.

City of Rockford – Asbestos removal plans set forth by Rockford, Illinois.

Draft Action Memorandum (PDF) – Details some of the environmental remediation efforts.

Google Books – The Textile American describes the Barber-Colman warp drawing machine.

Google Books – Habits of Industry: White Culture and the Transformation of the Carolina Piedmont describes the impact of the Barber-Colman warp drawing machine on the textile industry.

Hub Pages – Article on master inventor Colman.

Radio Museum – History of the Barber-Colman company.

Radio Museum – Newspaper article detailing an early garage door opener produced by Barber-Colman.

2008 Rockford Register Star Article – Discusses future plans for the site.

2008 Rockford Register Star Photo Gallery – Has some historical photos of the site. Also includes demolition activity from 2005.

2008 Rockford Register Star Article – Discusses the efforts to preserve records left at the abandoned factory.

2009 Rockford Register Star Article – Reports of a fire that occurred on the 3rd floor.

2010 Rockford Register Star Photo Gallery – Shows demolition of buildings 10 & 19 in November, 2010.

Google Books – The Textile American describes the Barber-Colman warp drawing machine.

Barcol Impressor – Vintage advertisement for a hardness check pump.

eBay Search “Barber Colman” – Has great photos of some of the products Barber-Colman produced.

Smithsonian – Barber-Colman had an early prototype computer with error checking.

Urban Entertainment Destinations: A Developmental Approach for Urban Revitalization – An extensive proposal for the Barber-Colman factory revitalization.

Excellent write-up! With the size of the exploration site, i’m glad that we had as much time as we did. It’s a true treasure that will soon be lost, I only wished to have been given the opportunity to see that place run in its heyday.

under active demolition go there while its still up

Great history wish there were more photos of the complex and the tunnels connecting the buildings underground. Both my grandfathers and some of my uncles retired from there. There is tons more in the buildings than just what was found in the video my grandfather said in various places. its a shame Rockford has no pride in there history.

I wanted to explore the tunnels, but a homeless person was living down there when I visited. I talked to him for a while. He had been systematically stripping the copper wiring out of the basement to survive.

Ken I am interested in tunnel system I have heard stories and been to a few spots but would like to get more info. Please contact me if possible Jmartin1384@gmail.com

I had to laugh as I was doing some searching for pics of industrial buildings and BC came up. I remember getting a tour of the place when I was back in Jr High. Read the article and noticed it was being torn down….what a shame

Good article. The story of Howard Coleman is indeed an American story. I especially admire his reluctance for celebrity. His first hire was Harry Severson, my grandfather (pg 10). They became partners and Harry became Chairman of the Board until his death in 1957. Mr. Lundin died two weeks before I learned of his book. On page 10 he describes how unfortunate it was none of Howard’s close associates wrote of their impressions of him. Not true. In 1976 I spent hours in Harry’s library reading letters between them and others. Mr. Lundin never knew this. Their politics were particularly interesting.

I created the index to Mr. Lundin’s book. If you still have access to your grandfather’s letters, I would be interested in seeing them, and, if you have any wish to have them catalogued, I would be happy to catalog and index them for you.

Another note: my brother worked in the print shop in the summers while he was in college in the late 1960s, and I worked in the print shop (secretary) from 1976-1978; as well, my mother worked (secretary) for the IT division until 1989. It was a GREAT company and was indeed employee- and family-oriented. During one of the last picnics I attended, photos of employees, company picnics, and the Barber-Colman News issues were being given away; I would have liked to have taken them all, so they could be kept forever (or, at least, my lifetime), but it didn’t happen that way. I’m hopeful SOMEONE has this material, and a huge thanks to the folks who rescued the 6th floor material, and to Midway Village for understanding the archival importance of these things.

WOW —-such a great article/blog/whatever ——I worked there in the mid 60’s (1960’s)

It was thew best place I ever worked—–even before OSHA they were safety conscious

and they believed in helping their employees—————-they matched dollar for dollar the money you spent on tools——-(I still have my 1st set of mikes they paid 1/2 for

My big problem was I never went back to work for them after nam—–But my fondest memories of ant place I ever worked was BC and the family atmosphere there

If I had ever gone back to the Midwest—–the 1st place I would have applied would have been BC

It makes me very sad to see this in this country

Roy Dawson

I worked at Barber Colman – Aircraft Products Division fresh out of college in 1979. My office was at 1354 Clifford Avenue, Loves Park, IL and it backed up to the Machine Tool plant on Windsor Road in Loves Park.

As a Mechanical Design Engineer, for aircraft products, it was decided that I needed to become well educated in the technology of gears and gear cutting. I spent a 6 month internship program at the Windsor Road plant learning everything there was to know about the technology of gear cutting and gear inspection. I have used that knowledge to great advantage throughout all of the successive years of my career.

As a industral historian, I also became curious about the history of the company, but thought it most curious that a “Textile Company” would become a preeminent manufacturer of aircraft products. In the course of doing research, I was told the following story:

Colman had developed the textile machinery for which he is well known. Along came WWI and there was a great need for parachutes. It was discovered that silk was the best material for maknig them, but it has different handling and weaving requirements than standard textiles. Colman was approached by the government to help them resolve the issues unique to weaving silk.

Among the things he discovered was that climate control of the weaving facility greatly enhanced the handling and manufacturing of the silk. Hence, he introduced and perfected some of his inventions in the area of HVAC which later became a fairly large component of his company.

Whem WWII came along, a new problem was discovered with respect to high altitude flight. Specifically, there was a need for HVAC (and pressurization) systems in large high altitude aircraft. Someone in the government remembered the successes of Colman with the handling of silk and HVAC, and recommended that he be contacted for his expertise. Since Colman already had experience with government contracts and with the new miniature electrical devices and control of HVAC systems, it seened a natural fit and B-C became one of the largest suppliers of electro-mechanical, electropneumatic, and pure pneumatic valves and controllers for aerospace.

The area on the map that is listed as the Powerplant, later became a facility for valve testing. Particularly for high temperature and high flow valves. While I was there in the early 80’s we conducted several tests in that facility and had to get there early to stoke the coal furnace to generate the hot air. There were many places where there were still open blade electrical switches to control the large fans and compressors used in for the air handling equipment. The majority of the light came from the large Gothic windows in the old brick building. We worked late into one night and were there during a thunder and lightning storm. The scene reminded me of something from an old Frankenstien film.

An additional piece of information, at one time B-C had an experimental hangar at RFD and owned several aircraft for corporate and experimental purposes. The Flight Test Group was dismantled and sold in the late 60’s or early 70’s.

I have a collection of old B-C promotional material about products that were developed in the 40’s through 70’s. Included in among them are interior and exterior facilities photos that might be of interest to you. In 2005 I returned to 1354 Clifford Ave, but the division was now owned by Smiths (British). While there Smiths was sold to GE Aviation which completely changed the complexion and culture of the company. It is no longer a family and employee friendly company. I left the company earlier this year.

Larry, I am originally from Boston, a Northeastern University engineer. I am now retired, living in Hartsdale, NY. I joined B-C in 1967 in Boston at one of their HVAC Branch offices, as sales engineer for building Automatic Temperature Controls and Air Distribution Products (both of which were made in the Love’s Park factory.

I was called to the factory in Feb. of 1969, and we moved our family (wife & three children) to Rockford. I began as sales engineer in ATC/AD ending up as the Marketing Manager for both divisions, working in the Love’s Park plant. During my tenure, I conducted guided tours of the plant’s, feeding guests at either the down-town or Loves Park cafeteria. Down town, we had an Air Distribution test facility that was the entire roof penthouse of the main building, quite a walk through the plant from the employee parking lot out back. To bring guests to the plant, I booked the B-C fan-jet Falcon and would meet the pilots at the B-C hanger at Rockford Airport early enough to take off, fly to (say) Boston or Atlanta or L.A. and return around 9:00 A.M. in Rockford, then take our guests “on-tour” which some times ment a lay-over at the Sweden House with manditory evenings at the Wagon Wheel or Playboy Club, then a return flight. Some days a one-day round trip begain with getting up at 3 A.M. flying who-knows-where and getting home around 1 A.M. the next day. At the airport we had three planes, the Falcon, a Rockwell Aero-Commander twin and a “V” tail Bonanza. The six pilots also maintained the aircraft (hence “light-touch” landings). The chief pilot John Hendricks (spelling?) was the Air Force pilot of Eisenhower. The hanger had three side-by-side B-C Overhead doors, whose dual center moveable mullions went up into two huge tin cans sticking up above the roof. Never flew in the Bonanza, but loved the Aero-Commander when the pilots would take me locally to be guest speaker, etc. I remember the difficulties of making electric air-craft window heating elements that would not interfere with the avionics.

I remember a story of Mr. Colman who returned during the late 30’s or early 40’s to Rockford from Massachusetts (many weaving factories – Lowell/Lawerence). His pilots landed his Lockeed Loadstar twin at the airport, and it was raining, so he went home, but just stared at his garage door without exiting the car, then drove to his office downtown, and after three weeks locked in his office, came out with a radio receiver/transmitter, to activate his garage door (during inclement weather). Neighbors wanted the same. Hence the birth of the B-C Overdoor Division. When touring with guests, I had a B-C Hand-Knotter, an ingenious device, invented and manufactured by Mr. Coleman, which by leather strap stayed on your hand leaving it free to do other things, but when one of the loom threads broke, you grabbed both ends, flicked the hand-knotter and voila! a weavers knot.

By In July 1974, we left Rockford and set up a design construct HVAC shop in San Diego – which business failed in 1975 and we moved here where I became Chief Mech Engr. for Wolff & Munier, Inc. staying on until my son’s hired me into their Consulting Firm in the early 1990’s.

Much more, even some photos, but for now,

Charlie Procell

I ran the Spring-coiler machine and heat-treating 60ft oven at the Park plant in Loves Park Il.I left because of management there. At the time I knew they took a number of picturers of my operation of the coiler SLEEPER HARTLEY # 4. Are the pic’s still around ???? I would be happy to pay a sum to get them!!! My machine was right next to the Slitter and Rolling Mill. would be happy to receive a reply Sincerely William E Webb

Worked for Barber Colman/Reed Chatwood from 1980 until 1998, when we were shut down by the bankruptcy court. Lots of memories when I looked at the pictures, spent all 18 years on Rock St. The photo of the lone chair was where they assembled textile machines, I worked in the paint shop, and we painted each and every machine that went out. Often times, we would work late into the night to get the finished machines cleaned up and touched up for shipping the following day.

Good article and pictures, would love to see more. I had a lot of old Reed Chatwood literature, but fortunately, they were lost during one of many moves.,

Hi Larry and Ed Haag,

I am very fascinated with your stories. If you should read this please contact me at clmnbr3@aol.com.

Thanks,

Adam

[

[…] abandoned Brach’s candy factory, much like the Barber-Colman plant, impressed me with its sheer magnitude. We were there for four hours before recognizing the time. […]

We were just exploring a few weeks ago in the exact same manner as you were. Went inside the building to take photos, went to the roof to get some good aerial shots of our building that is right across the tracks. Rockford Police pulled us off the roof at gunpoint and in cuffs. We ended up getting arrested for criminal trespassing and attempted burglary (as if there is anything of value in the building!). Three clean cut white adults with cameras!

Did you get permission to enter the building?

Check your email.

I worked in Textile Engineering in 1978 at the Kishwaukee plant. The most fun job I have ever had. We had 3500 employees and it was a close knit community. I sure miss the place.

What a great piece of history!! Severson was my great grandfather!!! Wish the building would have stayed so I could have one day gone to see it !

Good article. I worked in the computer room back in the 1970’s when they still had the big old Philco Tac 2000 computer that ran off the punched cards you’ve shown . It was a tube computer with 8K … of memory and generated tons of heat. I think I still have one of the original operators manuals for it. It was a great place to work .

My uncle Bob Eggleston was their corporate pilot. He flew their Falcon jet. I was lucky enough to get a ride in the copilots seat when I was a kid.We picked up some clients at Wright -Patterson Air Force Base and flew them to Chicago. Great memories doing the wheelie down the runway…

Those items you call “Uncut steel slugs for wrenches” are actually four cast iron resistor grids stacked loosely on top of each other. They are manufactured in several different sizes (resistance values) and mounted in various combinations in frames to be used for electric motor starting.

My grandmother worked at B-C for over thirty years and never complained once. She said it was a family environment and never had anything bad to say. I remember driving past it many times as a child and seeing the enormity of the complex for and all that it did for our country impresses me to this day. If there is any way to get any of her time cards, personnel record it would be most appreciated. That would be something that I can pass down thru the family history, Thanx, Jim

Living in Rockford, my friend and I want to get some pictures of this neat factory. So I was wondering how we get permission to visit and photograph this place? Thanks!

Is this still standing John?

[…] Barber-Colman Factory – Exploring America’s Gritty History – Great history wish there were more photos of the complex and the tunnels connecting the buildings underground. Both my grandfathers and some of my uncles retired from … […]

Hi I have this knotters I believe was made by barber colman company but not sure if some one could give me some info on it I would appreciate it. Just send me an email and I will send pics.Thank you